- Home

- Products

- Motor Grader

- Motor Grader PY320T

Motor Grader PY320T

Equipped with Cummins engine, PY320T motor grader adopts high-strength slewing bearing and overload protection worm gear box, suitable for heavy load conditions. This motor grader has an extensive working range due to its flexible blade suspension system and articulated frame.

- Operating weight: 28000KG

- Rated power: 246KW

- Blade width: 4620MM

| Basic specification | |

| Engine model | Cummins QSM11-C330 |

| Rated power | 246kW@2100rpm |

| Dimension(L×W×H) | 12500×3300×3700 (mm) |

| Operating weight (standard) | 28000KG |

| Performance specification | |

| Travelling speed, forward | 5.5/8.6/13.3/20.3/29/43 |

| Travelling speed, reverse | 5.5/13.3/29 |

| Tractive force (f=0.75) | 144KN |

| Operating specification | |

| Max. steering angle of front wheels | 49° |

| Max. lean angle of front wheels | 17° |

| Max. oscillation angle of front axle | 15° |

| Frame articulation angle | 25° |

| Min. turning radius using articulation | 9m |

| Blade | |

| Maximum lift above ground | 515mm |

| Maximum grading depth | 735mm |

| Maximum blade position angle | 80° |

| Blade cutting angle | 23°~73° |

| Circle reversing rotation | 360° |

| Moldboard width × height | 4620×695mm |

-

High Performance, Low Emission Engine The use of Cummins turbocharged engine enables the motor grader to achieve excellent productivity and low fuel consumption. The greater work speeds with high horsepower are provided thanks to the precise throttle control offered by the durable mechanical inline fuel injection system.

-

Reliable Transmission with Proven Performance The operation is simple and convenient thanks to the single-handle electro-hydraulic controlled power-shift transmission with 6 forward and 3 reverse gears. Paired with ZF-technology power-shift transmission, the Cummins engine makes the motor grader more dependable and simple to use, and suitable for all kinds of working environments.

-

Robust Chassis Frame Box-type chassis frame and advanced transmission allows it to execute heavy-duty tasks.

-

Superior Stability Hydraulic lock and auto lock/unlock NO-SPIN differential ensure outstanding stability and powerful traction.

-

Flexible Blade Mobility This motor grader has an extensive working range due to its flexible blade suspension system and articulated frame.

-

High Durability, Precise Control The drawbar is constructed with A-shaped and U-shaped frame for high durability and precise blade control.

-

Smooth Operation A turntable of four-inner gear guide type is included in the heat-treated rotating ring structure, which allows for smooth 360° rotation. The optimal curvature of the moldboard enables all types of soil to be moved freely and efficiently.

-

Ideal Axle Load Allocation Axle loads are optimally allocated for superior stability and high work efficiency even when cutting hard surfaces.

-

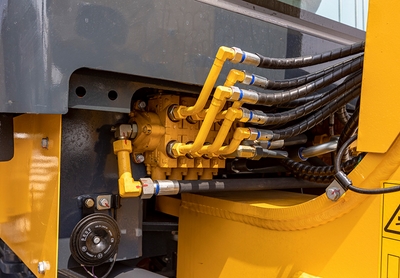

Reliable Hydraulics Every component can be fully leveraged because of the deployment of an efficient hydraulic system. Safety is ensured by a dependable hydraulic brake system.

-

Excellent Visibility The spacious cab is designed with a side pillar layout for an excellent visibility that gives operator confidence to maneuver in various working conditions. The moldboard and front tires are clearly visible due to the well-positioned blade linkage.

-

Work Tools and Attachments

Front Dozer Blades The front dozer, or front blade, is a piece of motor grader attachments that is mounted in the front of the vehicle for spreading gravel piles, or pushing materials in corners where is difficult to reach with the moldboard. -

Work Tools and Attachments

Rear Rippers & Mid-mount Scarifiers Attachments such as rippers and scarifiers are tools used for digging up asphalt, rocks or other hard materials that cannot be removed by the moldboard. The V-type scarifier can accommodate up to 11 teeth, the ripper also can accommodate 3-9 shanks. -

Automatic Leveling Device The automatic leveling device as a 2D machine control system enables precise height and slope control, giving a high flexibility in the selection of sensors and application fields.

-

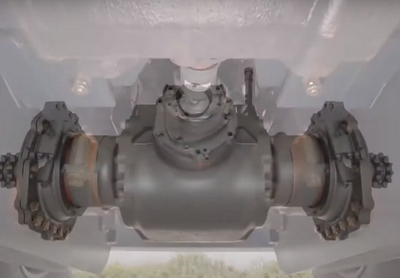

Rear Axle Drive System By using large-size rear drive axle, the reliability of the transmission is significantly improved.

-

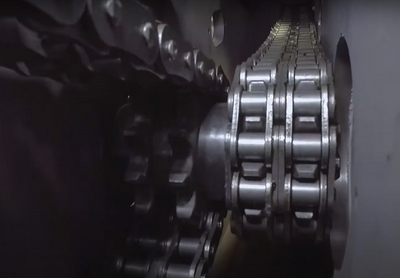

Double Row Roller Chain The double row roller chain has a greater tensile strength (26 tons) over peer and national standards.

-

- Motor Grader PY320T

Operating Weight 28000KG Rated Power 246kW Blade Width 4620mm

-

- Motor Grader PY350T

Operating Weight 28000KG Rated Power 268kW Blade Width 4920mm

-

- Motor Grader PY130H

Operating Weight 12000Kg Rated Power 97kW Blade Width 3658mm

-

- Motor Grader PY150H

Operating Weight 12000Kg Rated Power 110kW Blade Width 3658mm

-

- Motor Grader PY180H

Operating Weight 14500Kg Rated Power 132kW Blade Width 3658mm

-

- Motor Grader PY190H

Operating Weight 15600Kg Rated Power 142kW Blade Width 4268mm

-

- Motor Grader PY220H

Operating Weight 16100/15800Kg Rated Power 162/160kW Blade Width 4320mm

-

- Motor Grader PY240H

Operating Weight 20000Kg Rated Power 179kW Blade Width 4420mm

-

Worldwide Service Network

Worldwide Service NetworkWith our development in overseas markets, our service team's staffs are constantly increasing and we serve customers in over 50 countries.

-

Excellent Technology At the International Forefront

Excellent Technology At the International ForefrontSINOMACH-HI has established joint ventures with worldwide famous enterprises in the construction machinery industry.

-

The Quality of the national team you may always rely on.

The Quality of the national team you may always rely on.Our group owns the only national construction machinery research institute in China. With 60-year experience in manufacturing and 30-year experience in exporting, we know you better.

- Add: No.898 West Huang He Road, Changzhou city, Jiangsu Province, China

- Tel.: +86-519-86781388

+86-519-86752400 - E-mail: sales2@changlin.com.cn